5 Ways Forging Manufacturer Can Save You A Lot Money

The importance of manufacturing in the economic structure of a society is undeniable. Among various manufacturing processes, forging plays a significant role in producing some of the most vital components of several industries. Whether it’s the automotive industry or aerospace, the need for a reliable and cost-effective forging manufacturer is omnipresent.

Although the forging process can be a substantial investment, there are ways you can save money while ensuring high-quality outputs. Here are five insider secrets to help you maximize your savings when working with a forging manufacturer.

- Material Selection

Material selection is also key. While the decision largely depends on the final application of the part, some materials are more cost-effective to forge than others. For instance, carbon steel is generally less expensive than alloy steel or stainless steel. Communicate your requirements clearly with the manufacturer, and let them guide you in selecting the most cost-effective material that meets your needs.

- Batch Production

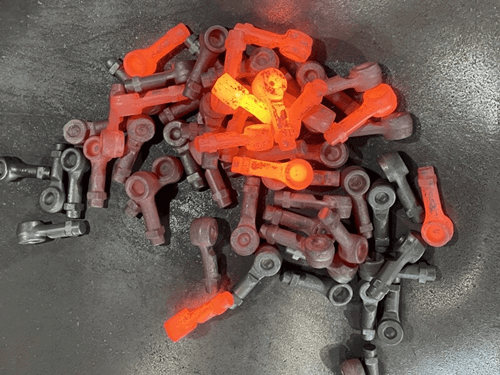

Batch production can dramatically lower the cost per unit of the forged item. In forging, a considerable portion of the total cost is tied to the setup of the forge for a specific part. By increasing the quantity of the parts you need forged at a single time, you can distribute the setup cost over a larger number of units, reducing the cost per piece.

- Partner with a Full-Service Manufacturer

A full-service manufacturer who can handle all stages of the forging process, including designing, forging, heat treating, machining, and finishing, can save you both time and money. You eliminate the need for multiple vendors, simplifying the supply chain and reducing administrative costs.

- Maintain Regular Communication and Long-Term Relationships

Maintaining regular communication with your forging manufacturer allows you to stay updated with the latest technological advancements, manufacturing techniques, and cost-saving methods. A strong, long-term relationship with your manufacturer can also lead to cost benefits. They may offer you discounts for loyalty or negotiate prices based on the promise of future work.

- Use Simulation Software

Finally, utilizing forging simulation software can lead to substantial cost savings. These applications predict potential forging defects, allowing you to optimize the process before actual production begins. This proactive approach can save you from expensive trial-and-error methods and the costs associated with defective parts.

Visit forging manufacturer, a supplier who offers the best quality forgings at an affordable price.