The Best Forgings Manufacturers Have The Following

The forging industry is characterized by intense competition and the continual evolution of technology. But amidst the vast sea of manufacturers, only a few manage to stand out and be recognized as the best in the business. So, what sets the best forgings manufacturers apart? Here are 5 distinctive characteristics that are common among the industry’s leading lights.

State-of-the-Art Technology & Equipment:

The foundation of any leading forgings manufacturer is their investment in the latest technology and equipment. This doesn’t merely mean having the most advanced machinery, but also consistently updating equipment to ensure precision, efficiency, and optimal production capacity. Automated systems, precision measurement tools, and innovative forging techniques are all signs of a manufacturer that is dedicated to maintaining its technological edge.

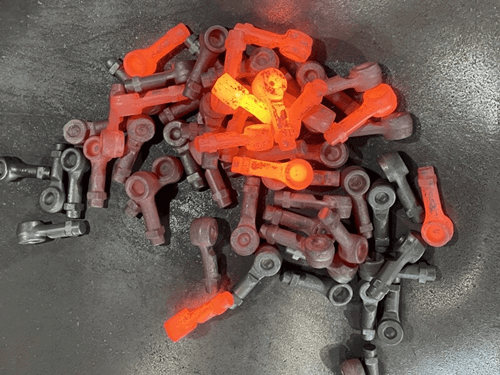

High-Quality Materials:

Superior end products begin with superior raw materials. The best manufacturers prioritize sourcing high-quality metals and alloys that will yield strong, durable forgings. This means not just meeting industry standards but often exceeding them, to ensure that their products stand out in terms of durability, strength, and performance.

Skilled Workforce:

Machines and materials are crucial, but it’s the human touch that often makes the biggest difference. Top manufacturers invest heavily in training their workforce, ensuring that they have a deep understanding of metallurgy, machinery, and the nuances of the forging process. A skilled workforce can adapt to changing demands, troubleshoot problems quickly, and maintain the consistent quality that clients demand.

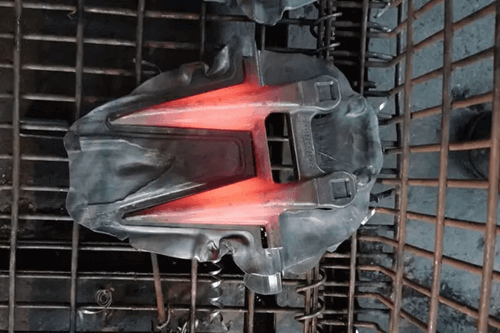

End-to-End Service:

From initial design consultation to final product delivery, the best manufacturers offer comprehensive services. This encompasses not just forging, but also services like heat treatment, machining, testing, and finishing. By providing end-to-end solutions, they ensure a seamless experience for their clients and maintain quality control throughout the production chain.

Robust Quality Control:

Last, but certainly not least, the best forgings manufacturers are obsessive about quality control. This means rigorous testing at every stage of the production process, from raw material inspection to final product quality checks. Leading manufacturers often have in-house testing facilities and adhere to international standards, ensuring that every product that leaves their facility meets the highest quality benchmarks.

Visit one of the reputable forgings manufacturers that’s is high rated for the quality and reliability of the forgings they produce.